Wastewater reuse is becoming more and more popular. There’s a shortage of clean water, and the environment is getting increasingly polluted. There have been many advances in wastewater treatment technologies, which have created many opportunities to reuse wastewater. Some examples are watering plants, industry, and daily life. Check out this article from ATS Water Technology to learn more about this trend!

1. What is wastewater reuse?

Wastewater reuse is all about using advanced technologies to clean wastewater so it’s clean enough to use again. This water can be used in different ways, like in production, factory cleaning, cooling systems, and watering plants in factories and industrial parks.

Today’s most popular wastewater reuse technologies include:

- Reverse osmosis (RO) membrane technology

- Ultrafiltration (UF) membrane technology

Wastewater reuse treatment is great because it helps us use clean water more efficiently, solves the problem of a global clean water shortage, and prevents water waste in the production and business process. This makes money for businesses, improves their products and brands, and helps keep the environment in balance while assisting companies to develop sustainably.

2. Standards for reusing wastewater

According to Circular No. 41/2018/TT-BYT, the current technical standard for clean water is National Technical Regulation QCVN 01-1:2018/BYT. The standards for reusing wastewater have been updated as follows:

| NO. | PARAMETER | UNIT | PERMISSIBLE LIMIT |

| Group A parameters | |||

| Microbiological parameters | |||

| 1 | Coliform | CFU/100 mL | <3 |

| 2 | E.Coli or Fecal Coliform | CFU/100 mL | <1 |

| Organoleptic and inorganic parameters | |||

| 3 | Arsenic (As) | mg/L | 0.01 |

| 4 | FCR | mg/L | Within 0.2 – 1.0 |

| 5 | Turbidity | NTU | 2 |

| 6 | Color | TCU | 15 |

| 7 | Odor, taste | – | No odor and strange taste |

| 8 | pH | – | Within 6.0 – 8.5 |

| Group B parameters | |||

| Microbiological parameters | |||

| 9 | Staphylococcus aureus | CFU/ 100mL | < 1 |

| 10 | Ps. Aeruginosa | CFU/ 100mL | < 1 |

| Inorganic parameters | |||

| 11 | Ammonium (NH3 and NH4+ expressed as N) | mg/L | 0.3 |

| 12 | Antimon (Sb) | mg/L | 0.02 |

| 13 | Barium (Bs) | mg/L | 0.7 |

| 14 | Borax and Boric acid (B) | mg/L | 0.3 |

| 15 | Cadmium (Cd) | mg/L | 3 |

| 16 | Lead (Plumbum) (Pb) | mg/L | 0.01 |

| 17 | Permanganate index | mg/L | 2 |

| 18 | Chloride (Cl–) | mg/L | 250 (or 300) |

| 19 | Chromi (Cr) | mg/L | 0.05 |

| 20 | Copper (Cuprum) (Cu) | mg/L | 1 |

| 21 | Hardness, expressed as CaCO3 | mg/L | 300 |

| 22 | Fluorine (F) | mg/L | 1.5 |

| 23 | Zinc (Zincum) (Zn) | mg/L | 2 |

| 24 | Manganese (Mn) | mg/L | 0.1 |

| 25 | Sodium (Na) | mg/L | 200 |

| 26 | Aluminium (Al) | mg/L | 0.2 |

| 27 | Nickel (Ni) | mg/L | 0.07 |

| 28 | Nitrate (NO3– expressed as N) | mg/L | 2 |

| 29 | Nitrite (NO2– expressed as N) | mg/L | 0.05 |

| 30 | Iron (Ferrum) (Fe) | mg/L | 0.3 |

| 31 | Selenium (Se) | mg/L | 0.01 |

| 32 | Sulfate | mg/L | 250 |

| 33 | Sulfur | mg/L | 0.05 |

| 34 | Mercury (Hydrargyrum) (Hg) | mg/L | 1 |

| 35 | Total dissolved solids (TDS) | mg/L | 1000 |

| 36 | Cyanide (CN) | mg/L | 0.05 |

| Organic parameters | |||

| a. Chlorinated alkanes | |||

| 37 | 1,1,1 – Trichloroethane | µg/L | 2000 |

| 38 | 1,2 – Dichloroethane | µg/L | 30 |

| 39 | 1,2 – Dichloroethylene | µg/L | 50 |

| 40 | Carbon tetrachloride | µg/L | 2 |

| 41 | Dichloroethane | µg/L | 20 |

| 42 | Tetrachloroethylene | µg/L | 40 |

| 43 | Trichloroethane | µg/L | 20 |

| 44 | Vinyl chloride | µg/L | 0.3 |

| b. Aromatic hydrocarbon | |||

| 45 | Benzene | µg/L | 10 |

| 46 | Ethylbenzene | µg/L | 300 |

| 47 | Phenol and phenol derivatives | µg/L | 1 |

| 48 | Styrene | µg/L | 20 |

| 49 | Toluene | µg/L | 700 |

| 50 | Xylene | µg/L | 500 |

| c. Chlorinated benzenes | |||

| 51 | 1,2 – Dichlorobenzene | µg/L | 1000 |

| 52 | Monochlorobenzene | µg/L | 300 |

| 53 | Trichlorobenzene | µg/L | 20 |

| d. Complex organic compounds | |||

| 54 | Acrylamide | µg/L | 0.5 |

| 55 | Epichlorohydrin | µg/L | 0.4 |

| 56 | Hexachlorobutadiene | µg/L | 0.6 |

| Pesticide parameters | |||

| 57 | 1,2 – Dibromo – 3 Chloropropane | µg/L | 1 |

| 58 | 1,2 – Dichloropropane | µg/L | 40 |

| 59 | 1,3 – Dichloropropen | µg/L | 20 |

| 60 | 2,4 – D | µg/L | 30 |

| 61 | 2,4 – DB | µg/L | 90 |

| 62 | Alachlor | µg/L | 20 |

| 63 | Aldicarb | µg/L | 10 |

| 64 | Atrazine and chloro-s-triazine derivatives | µg/L | 100 |

| 65 | Carbofuran | µg/L | 5 |

| 66 | Chlorpyrifos | µg/L | 30 |

| 67 | Chlordane | µg/L | 0.2 |

| 68 | Chlortoluron | µg/L | 30 |

| 69 | Cyanazine | µg/L | 0.6 |

| 70 | DDT and derivatives | µg/L | 1 |

| 71 | Dichlorprop | µg/L | 100 |

| 72 | Fenoprop | µg/L | 9 |

| 73 | Hydroxyatrazine | µg/L | 200 |

| 74 | Isoproturon | µg/L | 9 |

| 75 | MCPA | µg/L | 2 |

| 76 | Mecoprop | µg/L | 10 |

| 77 | Methoxychlor | µg/L | 20 |

| 78 | Molinate | µg/L | |

| 79 | Pendimetalin | µg/L | 20 |

| 80 | Permethrin Mg/t | µg/L | 20 |

| 81 | Propanil Uq/L | µg/L | 20 |

| 82 | Simazine | µg/L | 2 |

| 83 | Trifuralin | µg/L | 20 |

| Parameters of disinfectants and disinfection byproducts | |||

| 84 | 2,4,6 – Triclorophenol | µg/L | 200 |

| 85 | Bromate | µg/L | 10 |

| 86 | Bromodichloromethane | µg/L | 60 |

| 87 | Bromoform | µg/L | 100 |

| 88 | Chloroform | µg/L | 300 |

| 89 | Dibromoacetonitrile | µg/L | 70 |

| 90 | Dibromochloromethane | µg/L | 100 |

| 91 | Dichloroacetonitrlle | µg/L | 20 |

| 92 | Dichloroacetic acid | µg/L | 50 |

| 93 | Formaldehyde | µg/L | 900 |

| 94 | Monochloramine | µg/L | 3.0 |

| 95 | Monochloroacetic acid | µg/L | 20 |

| 96 | Trichloroacetic acid | µg/L | 200 |

| 97 | Trichloroaxetonitril | µg/L | 1 |

| Radioactive parameters | |||

| 98 | Gross alpha activity α | Bg/L | 0.1 |

| 99 | Gross beta activity β | Bg/L | 1.0 |

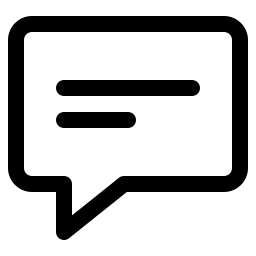

3. Effective wastewater reuse process

Our motto is to always put quality first, and we’ve been working closely with leading manufacturers worldwide to offer the best wastewater reuse solutions and technologies. Each solution is tailored to the specific needs of our customers.

To help everyone better understand the wastewater reuse process, we’d like to introduce a typical technological line that we’ve successfully deployed in Vietnam:

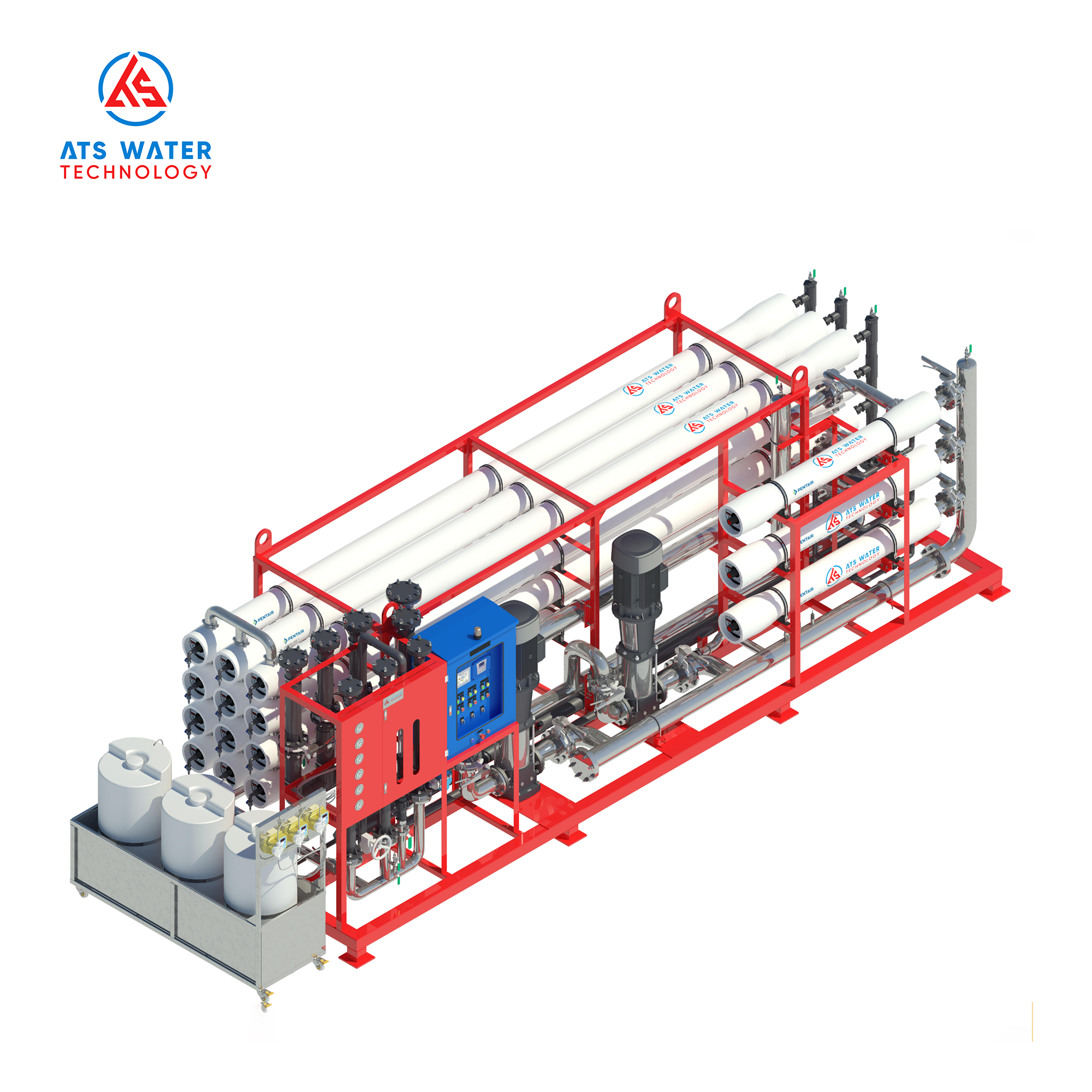

3.1. Pre-treatment stage

At this point, the water from the tank will be pumped into the Amiad self-cleaning filter. The filter size is 200 – 300 μm. This filtration process aims to remove some of the suspended solids in the water source. It also protects the ultrafiltration (UF) system from harmful effects from large dirt particles. After passing through the disc filter or screen filter, the water stream will be transferred directly to the UF system.

In the UF system, Pentair’s X-Flow UF membrane – with a 0.02 μm filter size and a special inside-out filtration mechanism – will remove all impurities smaller than bacteria, including colloids, emulsions, suspended solids, and most large molecules in the water. After filtration, the cleaned water source will be stored in the tank.

After UF, the water from the tank will be sent to the reverse osmosis (RO) system by a horizontal centrifugal pump and a high-pressure pump. A 5 μm Aqualine fine filter between the pumps removes dust and other small particles. This filter protects the high-pressure pump and the RO system from harmful agents.

The PWT antiscalant will also be added to the RO system during the wastewater reuse treatment process. PWT chemicals can effectively control the elements that cause scaling, like carbonate (CO32-), sulfate (SO42-), phosphate (PO43-), metal hydroxides, and silica. This helps the membrane last longer, makes treatment more efficient, and extends the time between Clean In Place (CIP) cycles, which saves money. On top of that, PWT chemicals are approved for use in food and drink by NSF/ANSI, and they’re safe for livestock.

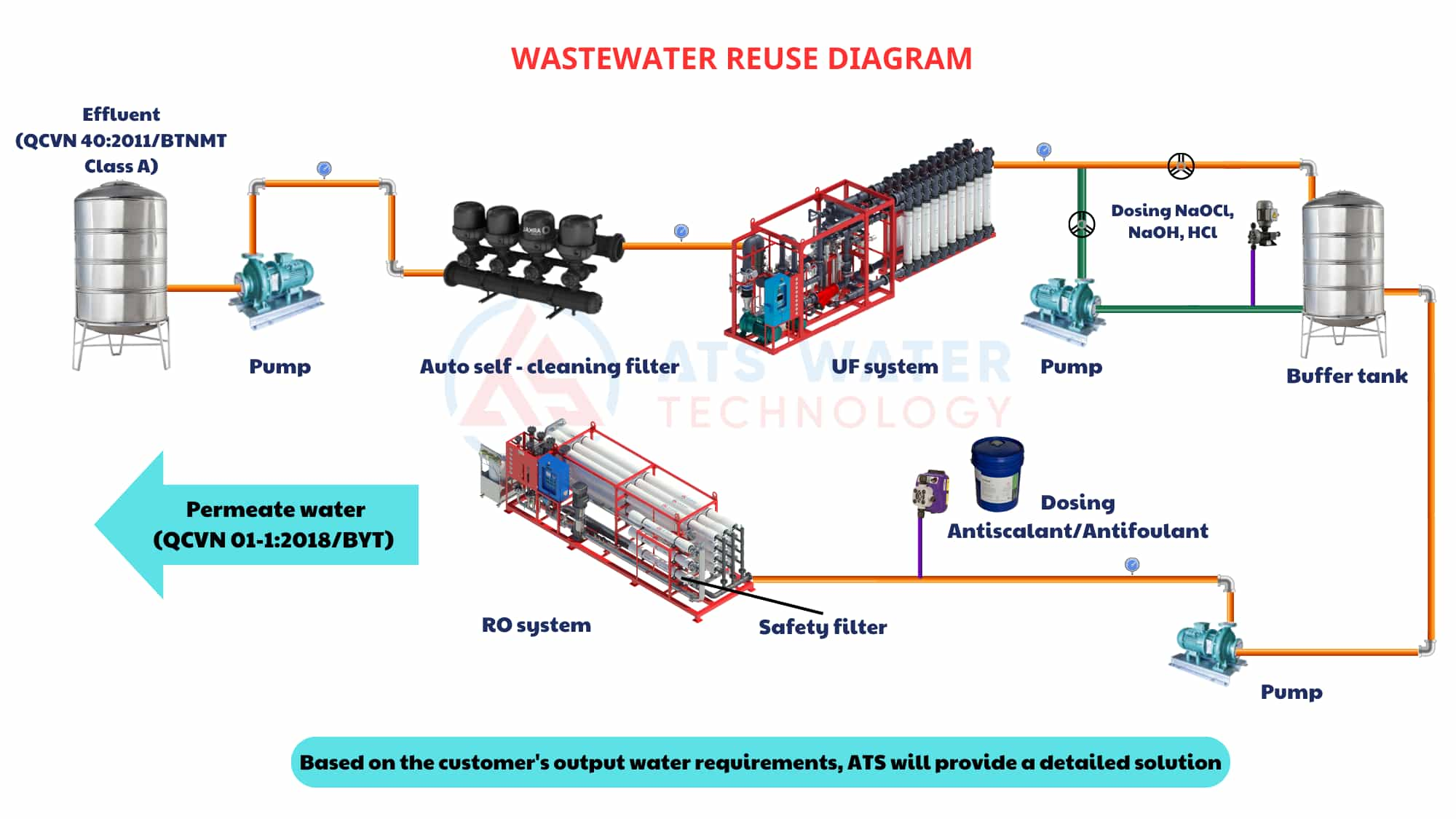

3.2. Main treatment stage

The main stage of the wastewater reuse process involves the reverse osmosis (RO) system, which is key to getting rid of impurities in the water. We recommend using the LG BW 400 AFR NanoH2O RO membrane with cutting-edge TFN (Thin Film Nanocomposite) membrane technology.

This membrane is special because the polyamide layer surface is coated with a special material with high antifouling abilities. This effectively prevents impurities from sticking to the membrane surface during operation.

This special structure allows the LG BW 400 AFR RO membrane to remove 99.89% of mineral salts, organic impurities, microorganisms, and other pollutants from pretreated wastewater. The quality of the treated water meets the domestic water standard, QCVN 08-1:2018/BYT and it can be reused for many purposes, such as daily life, production…

The RO membranes are put into the Pentair Codeline RO membrane housing, made with high-quality materials that can handle high-pressure situations. This housing design protects the RO membrane from outside damage and keeps water from seeping out while the system works. This helps the RO membrane last longer and works more smoothly and safely.

The combination of modern TFN technology that prevents fouling and a special membrane housing that can withstand high pressure makes the main treatment stage using RO effective at treating wastewater to meet clean water standards for various reuse purposes.

4. The benefits of reusing wastewater

With the population growing and the demand for freshwater increasing, treating and reusing industrial and domestic wastewater is more important than ever. After proper treatment, wastewater can become a valuable water source that can be used for many different things:

- Helping to protect precious freshwater resources. This allows us to rely less on freshwater resources and keeps the global balance.

- Reusing wastewater in industry cuts costs for wastewater treatment and discharge. By reusing wastewater, businesses can save a lot on treatment and discharge costs and ease the burden on the wastewater treatment system.

- When less wastewater is discharged into the environment, it reduces the negative impact on water, the environment, and natural ecosystems. So, it helps protect the environment, reduce pollution, and maintain ecological balance.

- Enterprises that reuse wastewater can get environmental certifications, like green or ecological certification. They can also meet ISO quality management and environmental standards. This can enhance the enterprise’s image and reputation, create a competitive advantage, and attract customers who care about environmental issues.

5. Frequently asked questions about wastewater reuse

Check out the FAQs below to learn more about wastewater reuse.

Is wastewater reuse safe?

With the right treatment, wastewater can meet health and safety standards. This makes it suitable for uses like irrigation or cooling.

Does wastewater reuse cost a lot?

Building a complex water treatment system can be expensive. However, in some cases, a wastewater reuse system’s operating and maintenance costs can be lower than supplying new water from natural sources.

What are the risks of wastewater reuse?

Even though processes for treating wastewater reuse are generally designed to remove toxic substances and bacteria, there’s still a risk of bacteria, organic compounds, and chemicals remaining in the wastewater. This has to be carefully controlled and monitored to ensure the safety of human health and the environment.

So, wastewater reuse is a great way to protect our water resources while helping businesses save money and be more sustainable. With the latest tech advances, wastewater reuse is getting easier and more effective. Contact ATS Water Technology for the perfect wastewater reuse solution for your needs.

ATS WATER TECHNOLOGY CO., LTD

- Headquarter: 54/18 Bui Quang La, Ward 12, Go Vap District, HCMC

- Branch office: 77 DHT10B, Dong Hung Thuan Ward, District 12, HCMC

- Consultation and support: (028) 6258 5368 – (028) 6291 9568

- Email: info@atswatertechnology.com

- Social media: Facebook | LinkedIn | Zalo Official

Solution

Solution  Technology

Technology  Application

Application