Lead-contaminated water is a major concern for factories and manufacturing facilities, directly impacting business operations and workplace safety. Many places fail to recognize the signs of lead contamination in water until severe consequences arise. Follow this article by ATS Water Technology to learn how to identify lead-contaminated water, its industrial hazards, causes of contamination, and effective treatment methods for industrial-scale applications.

1. What is Lead-Contaminated Water?

Lead-contaminated water contains lead (Pb) concentrations exceeding 0.01 mg/L. This is the allowable threshold for clean water used for domestic purposes, according to QCVN 01-1:2018/BYT standards. Note that this standard does not apply to drinking water.

2. How to Identify Lead-Contaminated Water

Lead-contaminated water typically has no distinct signs, as lead ions (Pb2+) in water are colorless, odorless, and tasteless. Therefore, water testing is the only method to confirm the presence of lead.

There are two ways to conduct water testing:

- Request testing from the water supplier: You can ask your water supplier to test the lead concentration in your water source. While convenient, not all suppliers may agree to this request.

- Self-sampling and laboratory testing: You can collect a water sample and send it to a professional laboratory for testing. This allows for greater control over the process and independent results.

Regular testing is essential to ensure water quality meets standards and does not disrupt industrial operations.

3. Impact of Lead-Contaminated Water on Industrial Production

Lead-contaminated water can have severe consequences for industrial production, including:

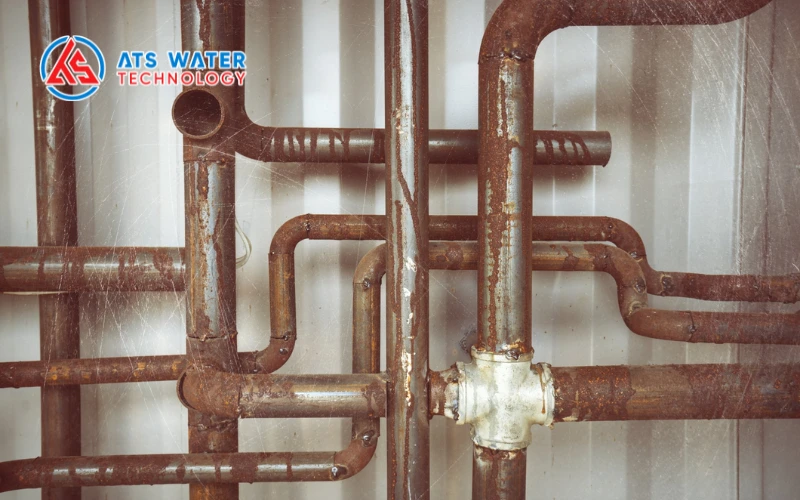

- Corrosion and equipment damage: Lead accelerates corrosion in piping systems and equipment, potentially leading to significant damage, reduced efficiency, and increased maintenance costs.

- Impact on product quality: In industries that use water in their products (e.g., food and beverage production), lead contamination can have serious health implications for consumers, especially children. According to the CDC, lead pollution in water can cause brain damage and nervous system issues in children, leading to developmental delays and learning difficulties. This can result in legal consequences, product recalls, and reputational damage for businesses.

- Health risks for workers: Exposure to high lead concentrations can cause severe health problems for workers. According to the WHO, lead poisoning can increase the risk of high blood pressure, cardiovascular issues, and kidney damage. This affects employee health, increases absenteeism, and raises medical costs for businesses.

4. Causes of Lead Contamination in Water

Lead contamination in water can result from various sources:

- Aging water supply systems: A primary source is old water systems that use lead pipes or lead-based solder. As water flows through these pipes, lead can dissolve into the water supply, causing contamination.

- Materials in water distribution systems: Components such as lead pipes, lead water tanks, lead faucets, or lead-based solder can contribute to contamination. When these materials degrade or corrode, lead is released into the water.

- Environmental pollution and industrial activities: Operations such as lead ore mining, metal production, plating, battery manufacturing, or the use of lead-containing substances in various industries can generate lead pollution and contaminate surrounding water sources.

- Groundwater sources: If groundwater contains lead, water from wells or underground sources may also be contaminated. This is common in areas with lead deposits or where water flows through lead-containing soil layers.

- Chemical exposure: The use of chemicals such as herbicides, pesticides, fertilizers, or other substances near water sources can contribute to lead contamination in the water supply.

5. Effective Treatment Methods for Lead-Contaminated Water

To ensure safe and lead-free water for industrial use, several treatment methods can be applied, including:

5.1. Reverse Osmosis (RO) Filtration

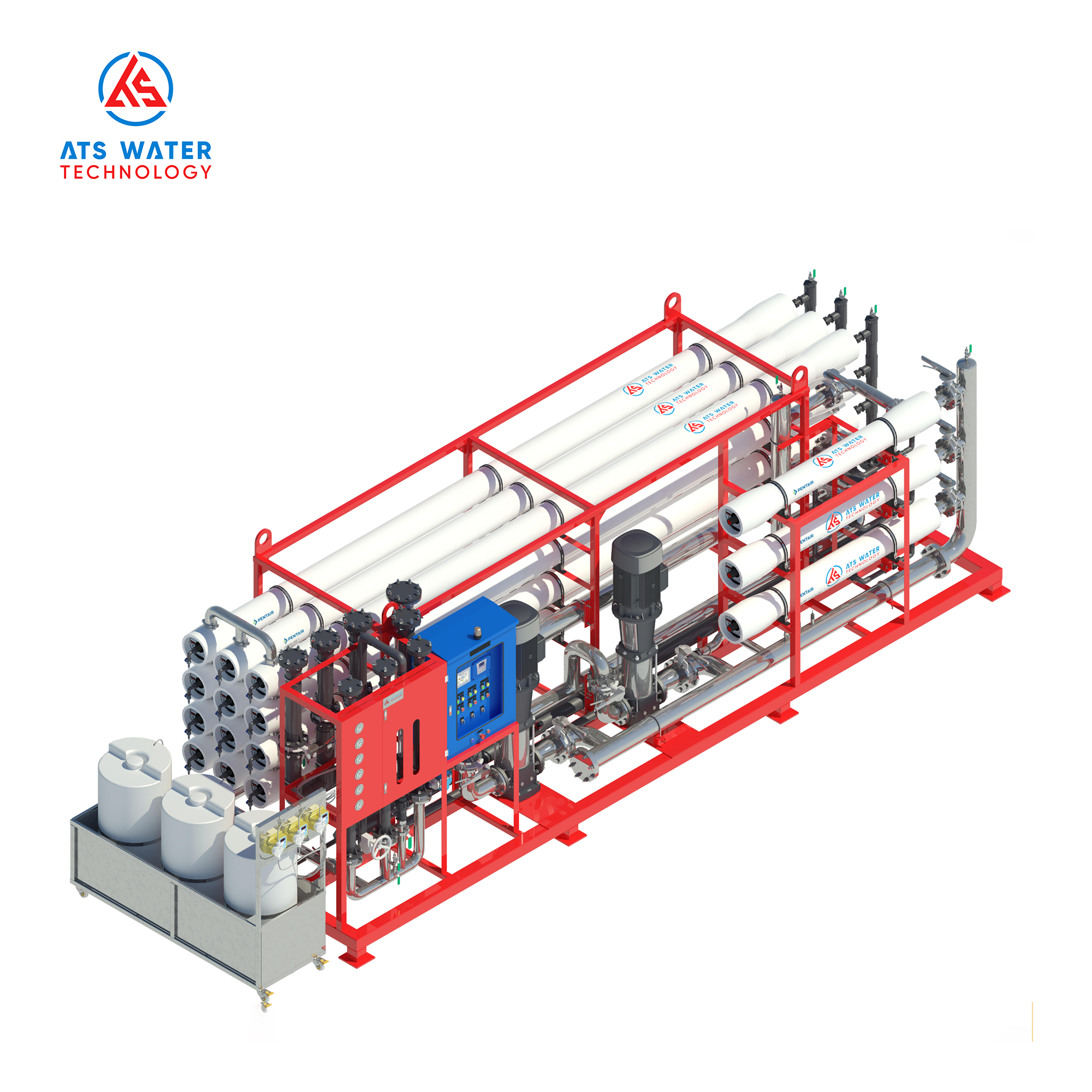

Reverse osmosis (RO) and nanofiltration membranes are two advanced technologies for treating lead-contaminated water. These methods operate based on the use of semi-permeable membranes to separate lead ions and other impurities from water.

- Reverse Osmosis (RO): In this process, water is forced through a semi-permeable membrane under high pressure, allowing only water molecules and small ions to pass while retaining heavy metal ions like lead. This helps reduce lead concentration in water to safe levels.

- Nanofiltration Membranes: Similar to RO but with slightly larger pore sizes, nanofiltration membranes can effectively remove heavy metal ions, including lead (Pb²⁺). This method typically consumes less energy and can be more efficient under certain conditions.

Both methods are highly effective in eliminating lead and other contaminants, ensuring clean and safe water for users.

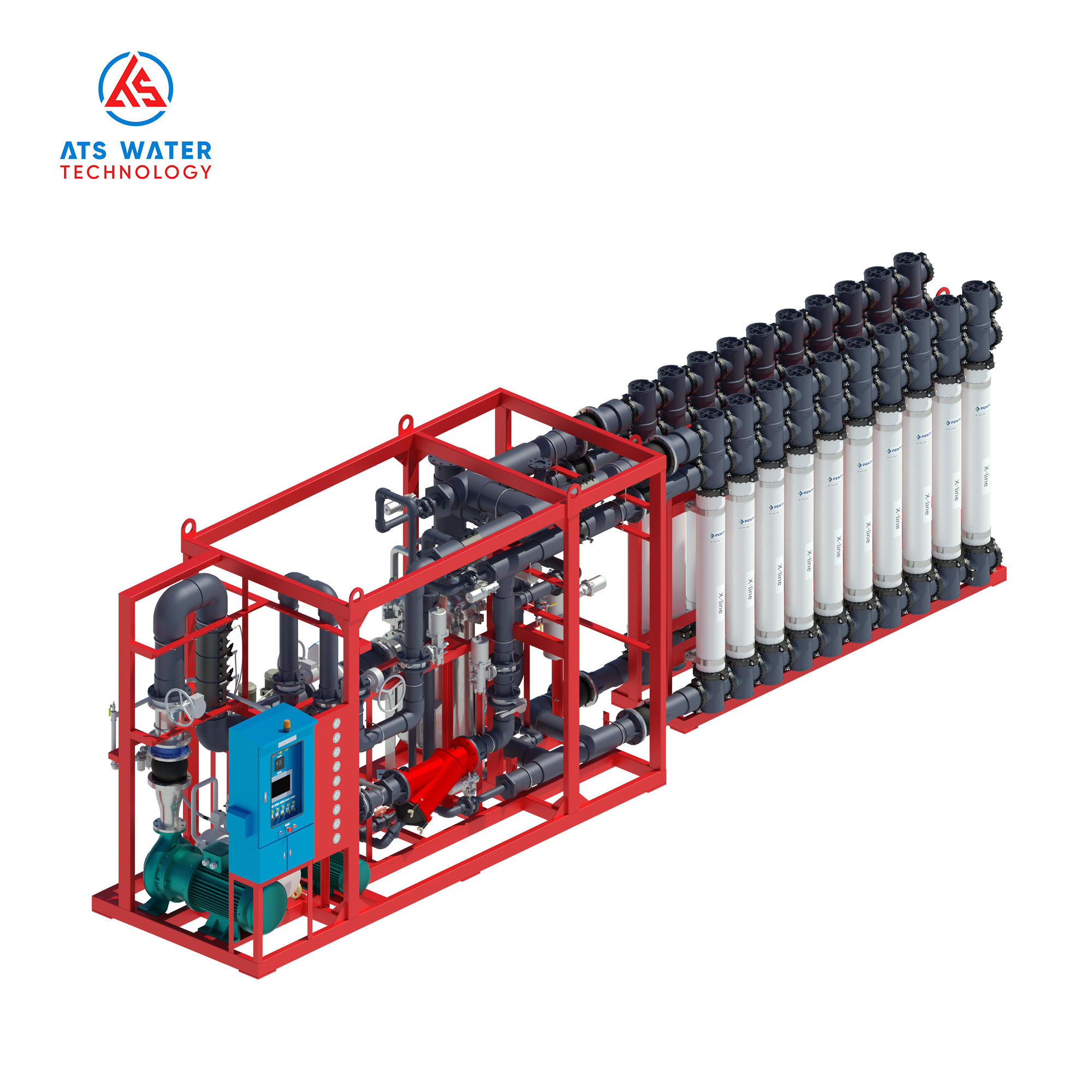

5.2. Using Ion Exchange Resin

This method utilizes ion exchange resins, such as strong acid cation (SAC) or weak acid cation (WAC) resins, to remove lead ions from water. The process works by exchanging lead ions in water with harmless ions present in the resin. When lead-contaminated water flows through a resin bed containing positively charged ions (such as sodium or calcium), the lead ions in the water are absorbed by the resin and replaced with hydrogen (H⁺) ions. This reduces the lead concentration in water, ensuring it meets safety standards for consumption.

5.3. Using Activated Carbon for Lead Adsorption

The use of activated carbon for lead removal is a common water treatment technique that relies on the adsorption capability of activated carbon to capture pollutants, including lead ions.

Activated carbon has a large surface area and porous structure, enabling it to adsorb lead ions and other contaminants as water passes through. When lead molecules come into contact with the carbon surface, they become trapped, allowing clean water to continue flowing. This process helps reduce lead concentration in water. However, the effectiveness of activated carbon in lead removal is limited compared to other methods.

The table below summarizes the key advantages and disadvantages of each method, helping industrial facilities choose the most suitable lead removal solution based on their specific needs and conditions.

| Method | Advantages | Disadvantages |

| Membrane Filtration (RO & Nano) | – Highly effective in lead removal.– Also removes bacteria, viruses, and other harmful contaminants, improving overall water quality. | – Requires a significant initial investment for equipment and installation.– Reverse osmosis requires high energy input for pressure generation, increasing operational costs. |

| Ion Exchange | – Can reduce lead concentration to safe levels as per strict regulations.– Effective for treating large water volumes. | – Requires periodic resin regeneration to maintain efficiency.– Regeneration and resin usage may generate solid waste or wastewater containing lead and other chemicals, requiring proper disposal. |

| Activated Carbon Adsorption | – Simple and easy-to-implement process. | – Requires frequent replacement.– Less effective in removing lead from water. |

Comparison Table of Lead Removal Methods

6. Frequently Asked Questions About Lead-Contaminated Water

What is the safe lead concentration in water?

The permissible lead concentration in domestic and industrial water should not exceed 0.01 mg/L, according to the QCVN 01-1:2018/BYT standard.

How can I determine if my water is contaminated with lead?

The only reliable way to confirm lead contamination is through water testing. You can request testing from your water supplier or collect a sample and send it to a certified laboratory for analysis.

What are the treatment methods for lead-contaminated water?

Treatment methods include adsorption, ion exchange, membrane filtration, distillation, and chemical precipitation. Each method has its advantages and limitations, depending on specific conditions and requirements.

How does RO membrane technology treat lead-contaminated water?

Reverse osmosis (RO) technology applies pressure to force water through a semi-permeable membrane, removing lead ions (Pb²⁺) and other impurities.

Treating lead-contaminated water is a crucial task for industrial facilities, ensuring compliance with environmental regulations, protecting human health, and improving product quality. Various treatment methods, such as adsorption, ion exchange, and membrane filtration, offer distinct advantages and limitations. Choosing the right method is essential for achieving optimal results.

If you are looking for effective water treatment technologies and solutions for your facility, contact ATS Water Technology for detailed consultation via the information below:

ATS WATER TECHNOLOGY CO., LTD

- Headquarter: 54/18 Bui Quang La, Ward 12, Go Vap District, HCMC

- Branch office: 77 DHT10B, Dong Hung Thuan Ward, District 12, HCMC

- Consultation and support: (028) 6258 5368 – (028) 6291 9568

- Email: info@atswatertechnology.com

- Social media: Facebook | LinkedIn | Zalo Official

References

- About childhood lead poisoning prevention. (2024, May 23). Childhood Lead Poisoning Prevention. https://www.cdc.gov/lead-prevention/about/index.html

- Basic Information about Lead in Drinking Water | US EPA. (2024b, November 21). US EPA. https://www.epa.gov/ground-water-and-drinking-water/basic-information-about-lead-drinking-water

- Chowdhury, I. R., Chowdhury, S., Mazumder, M. a. J., & Al-Ahmed, A. (2022). Removal of lead ions (Pb2+) from water and wastewater: a review on the low-cost adsorbents. Applied Water Science, 12(8). https://doi.org/10.1007/s13201-022-01703-6

- Lead exposure symptoms and complications. (2024, April 10). Childhood Lead Poisoning Prevention. https://www.cdc.gov/lead-prevention/symptoms-complications/index.html

- World Health Organization: WHO. (2024, September 27). Lead poisoning. https://www.who.int/news-room/fact-sheets/detail/lead-poisoning-and-health

Solution

Solution  Technology

Technology  Application

Application